PUNCHING TECHNOLOGY

Our production capabilities:

Manufacturing according to your specifications

Benefit from our know-how in the field of punching tool construction for the production of high quality special parts according to drawings.

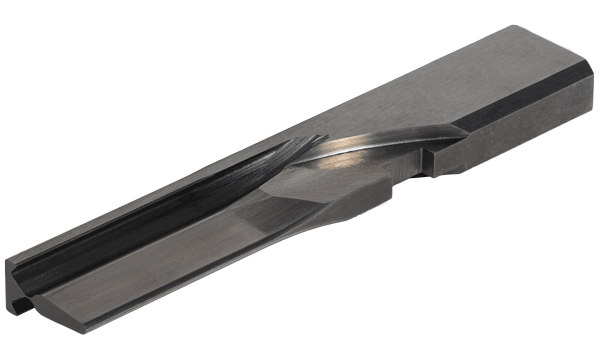

Specialization on cutting and forming punches

NONNENMANN is specialized in the production of cutting and forming punches as well as the corresponding matrices made of hard metal, HSS and ceramics.

Various types of production

With the various types of production, flat and profile grinding, wire cutting, sink erosion and polishing, we can offer round parts to max. Ø 100 x 150 mm and squared components to max. 150 x 100 x 150 mm, with a tolerance accuracy of up to ± 0.002 mm.

Long service life and wear resistance

The selection of a coating such as TiN, TiCN and DLC guarantees a long service life and wear resistance of the components and can also be included in our scope of delivery if required.

Punching technology from NONNENMANN

CONTACT US NOW

Use the advantages of our extended workbench and concentrate on your core business.