AUTOMATION

Everything from a single source: components, installation, CE approval and training

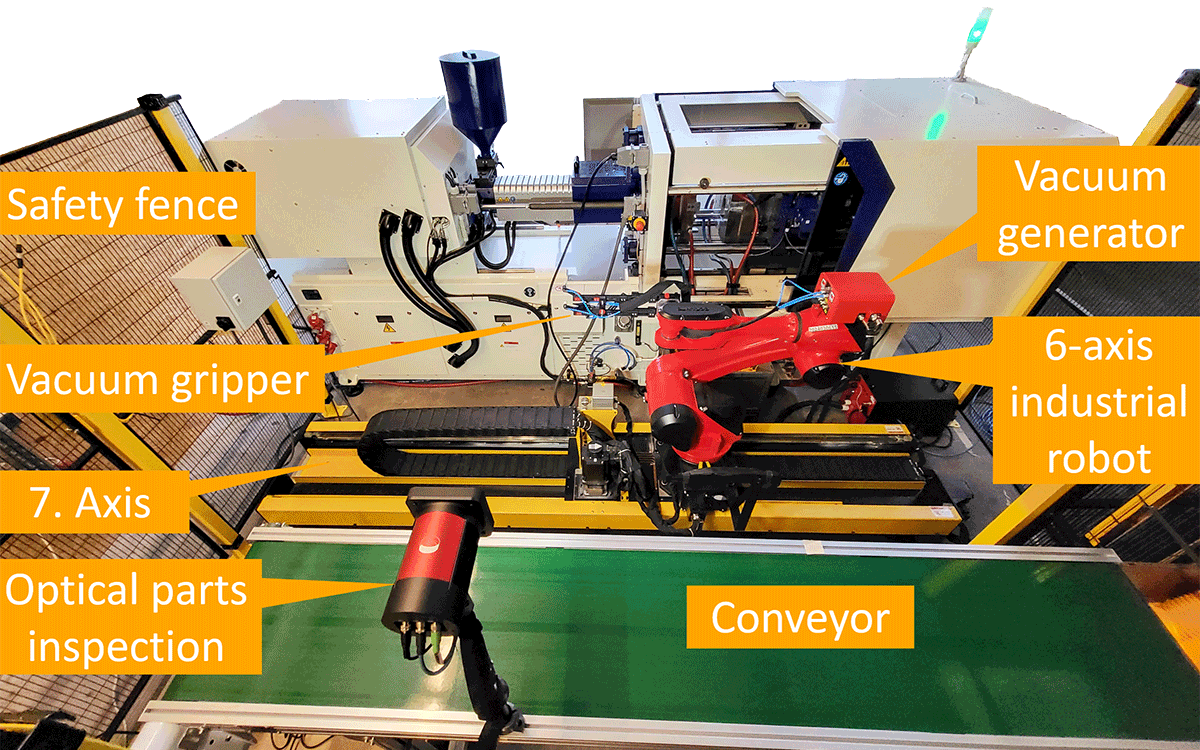

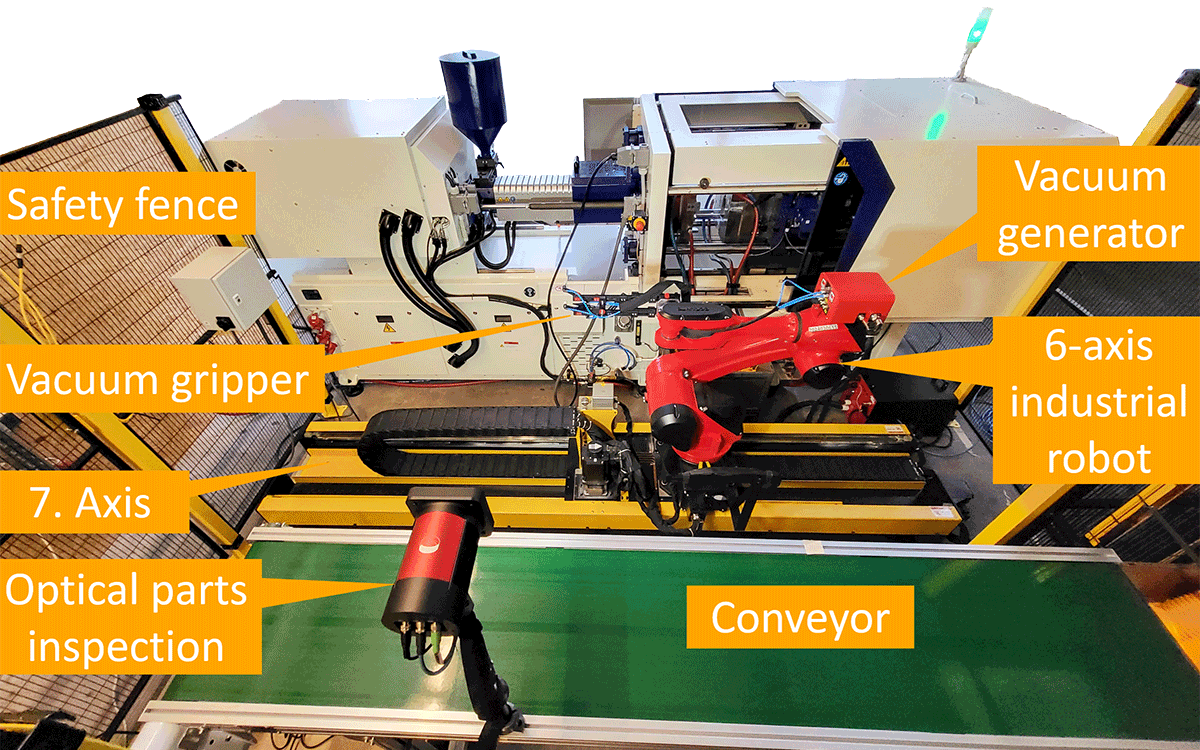

Our automation solution includes a 6-axis industrial robot, 7th axis, vacuum gripper and generator, AI-supported optical parts inspection, conveyor belt and a safety fence with safety system.

On request, we can install the automation system, carry out CE approval and train your employees. To make it easier for you to get a quote, we have developed a configurator that allows you to configure your automation system in just two minutes.

INDUSTRIAL ROBOT NoRA

The NoRA industrial robot can be used for component removal, insertion of inserts, sprue removal, removal via a conveyor belt or component inspection and offers a repeatability and positioning accuracy of up to ±0.03mm.

Speed in a straight line

1,5 m/s

1,5 m/s

Max. Temperature in operating range

40°C

40°C

Variants

3 robots for different loads and ranges

3 robots for different loads and ranges

Optional accessories

7th axis, vacuum generator and gripper

7th axis, vacuum generator and gripper

Software

Intuitive graphical user interface for programming the robot

Intuitive graphical user interface for programming the robot

Scope of delivery

6-axis robot, control cabinet, control panel with touchscreen, software, cables

6-axis robot, control cabinet, control panel with touchscreen, software, cables

NoRA0940/5

Maximum range

940 mm

940 mm

Maximum load

5 kg

5 kg

Repeat accuracy

± 0,05 mm

± 0,05 mm

NoRA0700/7

Maximum range

700 mm

700 mm

Maximum load

7 kg

7 kg

Repeat accuracy

± 0,03 mm

± 0,03 mm

NoRA1500/10

Maximum range

1500 mm

1500 mm

Maximum load

10 kg

10 kg

Repeat accuracy

± 0,05 mm

± 0,05 mm

7.Axis

The industrial robot can be extended by a 7th axis to further increase its flexibility. There is a choice of 7th axes with travel ranges from two to five meters. The 7th axis works via plug-and-play with all NoRa robots.

Vacuum generator

For use with vacuum grippers, the robots can be extended with a vacuum generator with a compressed air consumption of 3.2 l/min and a nominal output of 11 watts for two suction circuits.

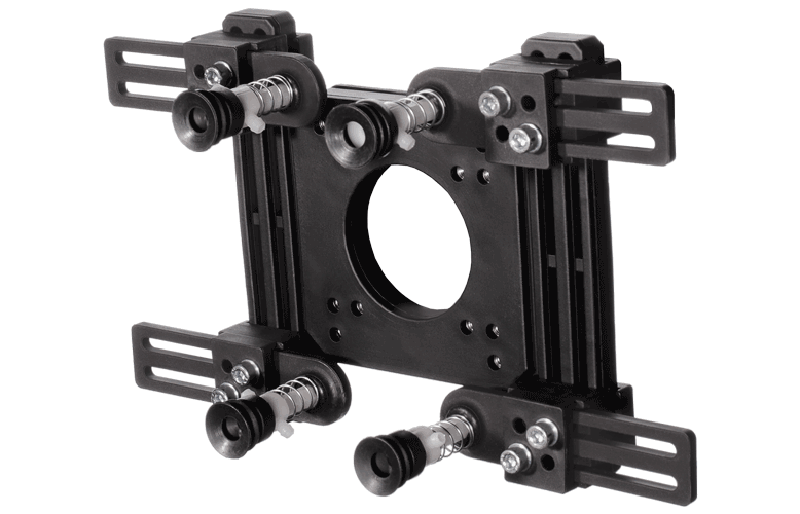

Vacuum gripper

Our plastic vacuum grippers are lighter than comparable aluminum grippers. You can assemble your gripper according to your requirements using a modular system.

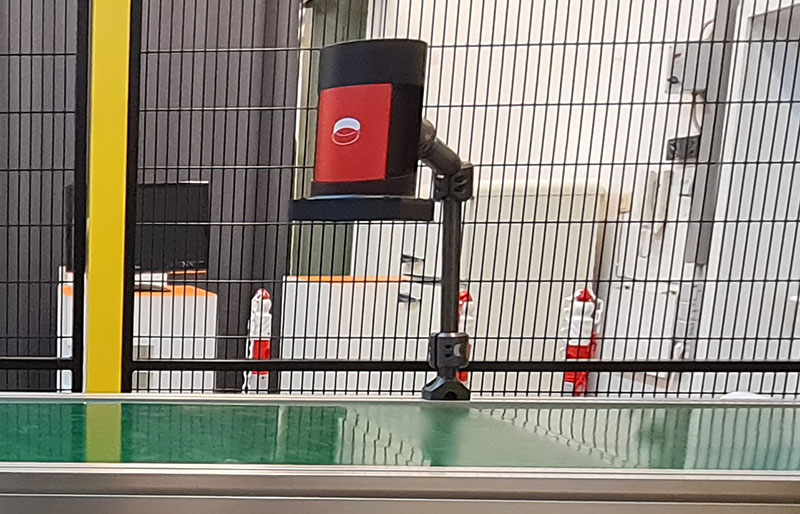

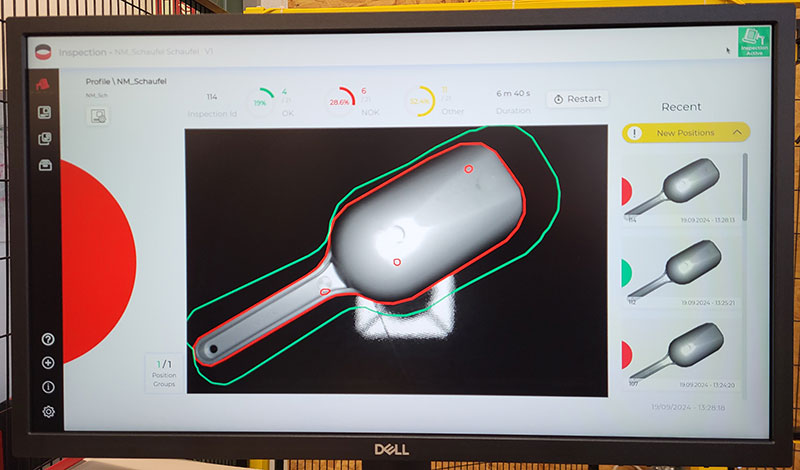

AI-supported optical parts inspection

The camera is initially presented with 20 - 30 good parts and the AI is trained accordingly. Both stationary parts and parts moved by a conveyor belt or a robot are recognized. The camera has a zoom and adaptive anti-reflection lighting.

Inspection cycle time

~0,3 seconds

~0,3 seconds

Maximum part speed

0,75 m/s

0,75 m/s

Trigger

Automatic, manual, PLC, Trigger-in

Automatic, manual, PLC, Trigger-in

Detection and positioning

autonomous

autonomous

Connectivity

Profinet, Ethernet/IP, TCP/IP, digital I/O, discrete I/O

Profinet, Ethernet/IP, TCP/IP, digital I/O, discrete I/O

Scope of delivery

Inspection camera, camera mount, mimic computer, 21-inch full HD monitor, software, mouse and keyboard

Inspection camera, camera mount, mimic computer, 21-inch full HD monitor, software, mouse and keyboard

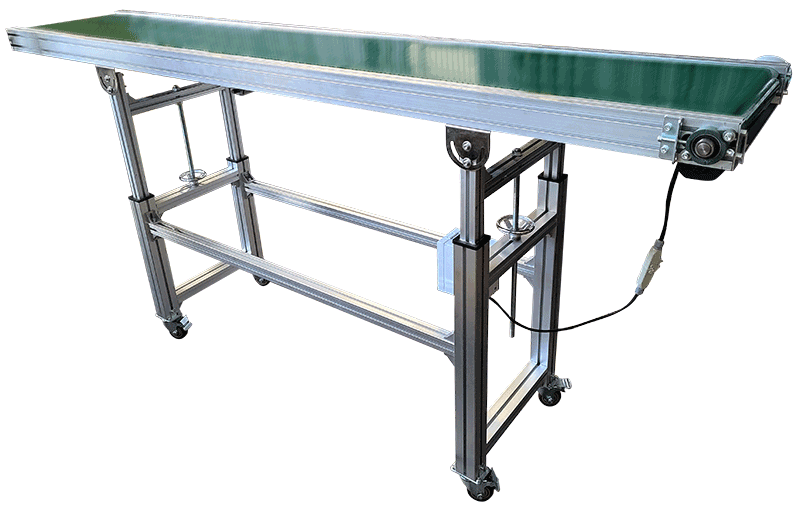

Conveyor

Conveyor belts are available in lengths from one to five meters. All conveyor belts can be used up to 80°C and have 2 mm thick PVC belts with adjustable speed.

Conveyor belts in the lengths

1000 to 5000 mm

1000 to 5000 mm

Maximum speed

10 m/min adjustable

10 m/min adjustable

Adjustable working height

700 - 1500 mm

700 - 1500 mm

Maximum load

15 kg

15 kg

Treadmill width

400 mm

400 mm

Total width

500 mm

500 mm

Safety fence and security system

The safety fence can be assembled in a modular system. We offer fence elements in lengths of 200 - 1400 mm. Swing doors and grilles with pass-through are offered with appropriate safety systems that prevent employees from entering the safety area during operation.

Fence height

2000 mm

2000 mm

Length of the fence elements

200 - 1400 mm

200 - 1400 mm

Modular system

Simple configuration

Simple configuration

Quick mounting system

Simple assembly

Simple assembly

Installation, CE approval and training

Our aim is to simplify the changeover to automation. That's why we offer a complete solution. On request, we can handle the installation of all components from robots to safety fences, as well as CE approval and user training. We have also developed a configurator to make it easier for you to get a quote.

Automation configurator

You too can benefit from automated production

Configure your automation in just two minutes. You can then have your configuration sent to you by e-mail with just one click.