Flow measurement

Dirt, lime and rust

Electronic measuring device

Automatic monitoring

Technical specifications

Flow measurement HT (high temperature range)

scope of delivery

IO-Link adapter

FREQUENTLY ASKED QUESTIONS

The FAQ’s for flow measurement

Which temperature control channel should be monitored?

Either the temperature control of the complete mould is monitored or only individual circuits are monitored if, for example, a critical channel (small cross-sections, many riser holes, channel length, etc.) is known.

Is the measuring instrument used on the flow or return line?

Usually, measurements are taken on the return flow of the mould in order to be able to draw conclusions about the causes in case of deviations. Changes inside the mould become visible. The measurement of the flow is usually covered by the temperature control unit, but if necessary the measuring device can also be used at the flow.

What can I do if the measured actual parameters do not correspond to the target values?

The determination of changed flow and temperature values is only the first step. It is crucial to react to them, analyse the causes and optimise them to ensure an ideal process again.

In order to make injection moulds with reduced flow values fit for production again, NONNENMANN offers with the cleaning devices of the series PropNew simple helpers for cleaning the temperature control channels.

NONNENMANN’s program also includes the leakage tester, with which tools can be checked for leakage in advance.

What can be the reasons for lower flow rates?

The causes can be found in the form as well as in the periphery. In the course of production and the mould life cycle, the temperature control channels can become clogged with dirt, lime or rust, depending on the water quality. This reduces the cross section and thus also the required flow of the temperature control system. As a result, the temperature control effects determined in the mould design are no longer achieved. Leaks in the hoses are also a possible source of error. Over the course of time, this leads to negative effects on the overall process, with longer cycle times and moulded part defects causing higher costs.

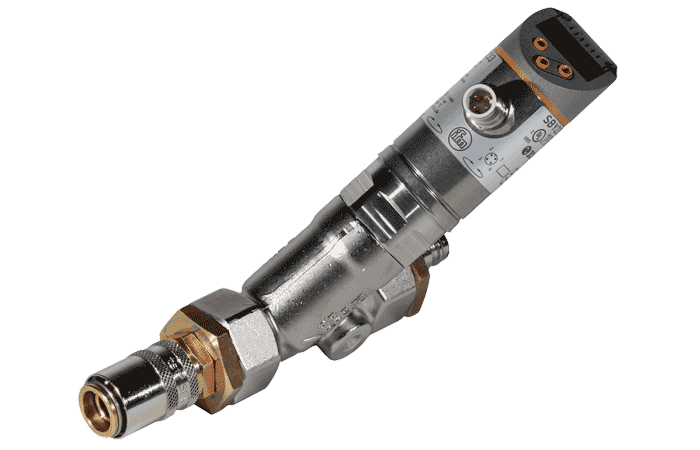

How is the measurement by the sensor performed?

The piston resting in the valve seat of the housing is lifted against the spring force by the flowing medium. The piston position is scanned by a magnetic field sensor and is output as an analogue signal. The spring force causes a safe return of the piston to the initial position when the flow decreases.

How is the measuring accuracy?

For flow monitoring, the accuracy is ± (4% of measured value + 1% of full scale).

For temperature monitoring, the accuracy is 3 K.

Which materials were used in the sensor?

Durch die Werkstoffauswahl, Edelstahl 1.4404 und FKM-Dichtungen, erfüllt das Messgerät die Anforderungen im Werkzeugbau, in der Instandhaltung und in der Kunststoffverarbeitung.

CONTACT US NOW

Ensure a stable production process in your injection moulding shop.

Jochen Schwegler

Consultant Plastic Injection Molding/Mold Making/Project Planning

+49(0)7181/4087-217

+49(0)7181/45351

+49(0)152/09 01 11 63

j.schwegler@nonnenmann.net