PROCESS OPTIMIZATION

Optimize your production processes by using cost- and time-saving periphery for the injection molding area.

PROCESS OPTIMIZATION

Optimize your production processes by using cost- and time-saving periphery for the injection molding area.

PROCESS OPTIMIZATION

Optimize your production processes by using cost- and time-saving periphery for the injection molding area.

THE POTENTIAL

Process optimization frees resources and increases your competitiveness.

30% of set-up times can be saved in many injection shops

- Remaining set-up time

- Saved setup time

THE CHALLENGE

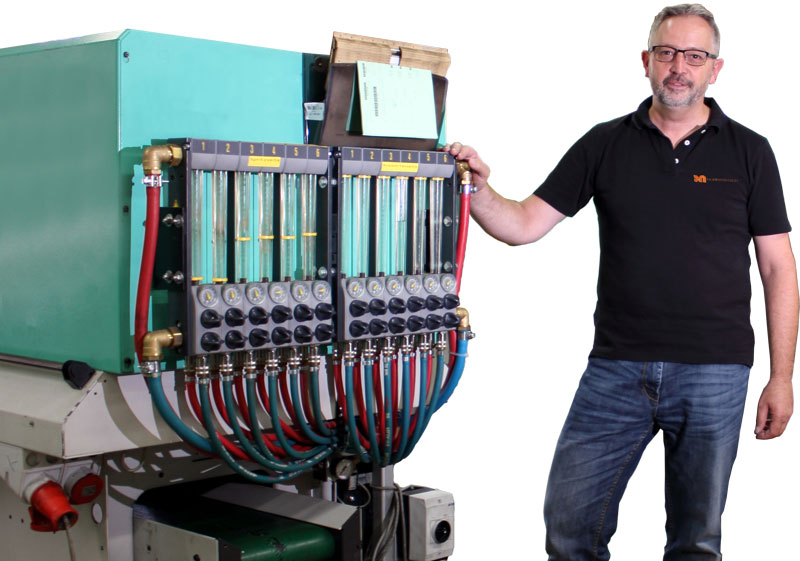

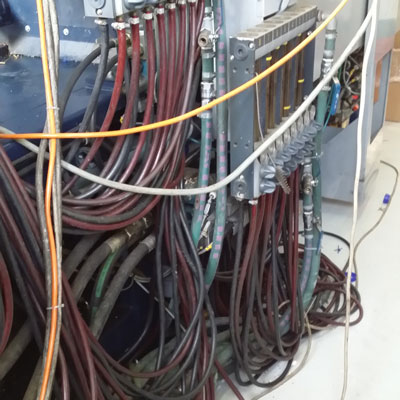

Did you know? Outdated setups often prevent efficient production.

The actual state

The consequences

THE VIEW FROM OUTSIDE

We continuously advise clients on the optimization of their processes. Take advantage of our experience.

Through a targeted review of the current processes and the identification of optimization potential in production processes, the use of cost-saving and time-saving peripherals for the injection molding sector and the training of your employees, you also benefit from our many years of experience.

In contrast to the competition, we offer you the complete package, by providing analysis, project planning, optimization of production, setup workshops and the selection of the right components from a single source. This includes the distribution, flow measurement, machine tubing, multi-couplings, bulkheads and their assembly. In addition, we offer you the ideal cleaning device for temperature control channels, including documented initial adjustment and instruction.

The target group of our workshops are: entrepreneurs, project managers, production managers, masters, adjusters, mold builders, maintenance engineers.

1-DAY WORKSHOP

PROJECTING

600 €*

- Assessment of injection molding machines and molds

- Demonstration of different temperature control variants

- Optimization proposals

- Tubing of injection molding machines and molds

- Injection molding peripherals

- Maintenance

- Work safety

- Project offer

2-DAY WORKSHOP

PROCESS OPTIMIZATION AND PROJECTING

1.800 €*

- Assessment of injection molding machines and molds

- Demonstration of different temperature control variants

- Optimization proposals

- Tubing of injection molding machines and molds

- Injection molding peripherals

- Maintenance

- Work safety

- Project offer

- Optimization training with your training team

NET-PRICE ORDER 5.000 € OR MORE

CREDIT FOR PROJECTING

-600 €

* When you issue a project planning with a net order value of € 5000, you will be credited with the costs of the project planning.

CONTACT US NOW

Optimize your production processes and increase your competitiveness.

Jochen Schwegler

Consultant Plastic Injection Molding/Mold Making/Project Planning

+49(0)7181/4087-217

+49(0)7181/45351

+49(0)152/09 01 11 63

j.schwegler@nonnenmann-gmbh.de