SHOWROOM

Get an impression of our products for yourself

We offer our customers and interested parties the opportunity to get a first-hand impression of our products in our new showroom.

During a personal appointment, we will show you exactly the products you are interested in. Book your appointment today!

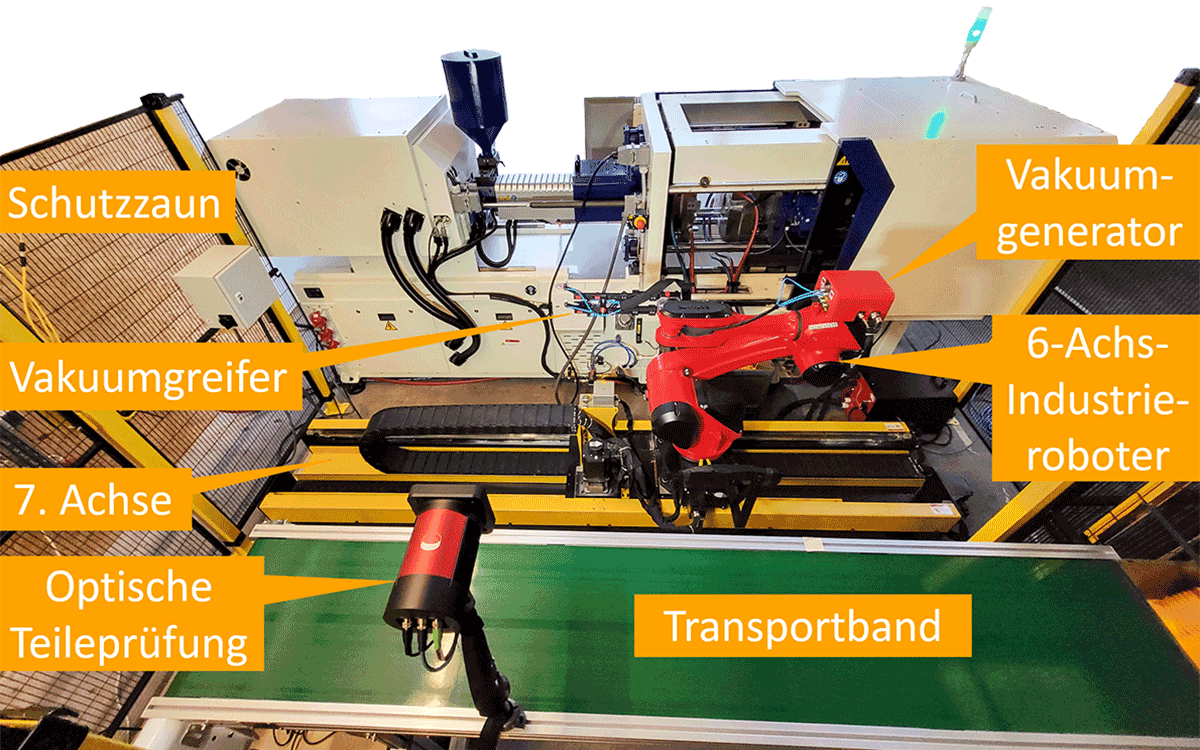

AUTOMATION WITH AI-POWERED PART INSPECTION

A highlight of our showroom is the demonstration of our automation solution for plastic injection molding, including a 6-axis industrial robot and AI-powered part inspection.

6-Axis Industrial Robot

optionally available with a matching vacuum generator

optionally available with a matching vacuum generator

Quality Control

AI-powered optical part inspection

AI-powered optical part inspection

Conveyor Belt

height-adjustable, max. length: 5m

height-adjustable, max. length: 5m

Safety Fence

including safety system

including safety system

Gripper Technology

lightweight aluminum vacuum grippers in a modular design

lightweight aluminum vacuum grippers in a modular design

Services

optionally, we handle installation, CE approval, and training

optionally, we handle installation, CE approval, and training

Kärcher IB 10/15 L2P Advanced

Purpose of use

Cleaning of mold surfaces

Cleaning of mold surfaces

Special feature

Integrated dry ice production from CO₂

Integrated dry ice production from CO₂

Advantage

Immediately ready for use, thorough cleaning, no dry ice pellets required

Immediately ready for use, thorough cleaning, no dry ice pellets required

Cleaning device PropNew

Purpose of use

Internal mold cleaning

Internal mold cleaning

Optional

Measurement of flow rate and pH value

Measurement of flow rate and pH value

Advantage

Ensuring optimum efficiency of temperature control systems

Ensuring optimum efficiency of temperature control systems

NoWMOVE-MSB

Purpose of use

Turning, opening and servicing

Turning, opening and servicing

Special feature

Integrated air cushion function

Integrated air cushion function

Advantage

Easy and safe movement of molds up to 2.5t

Easy and safe movement of molds up to 2.5t

Products for Plastic Injection Molding

In addition to the products mentioned above, we also provide consultation in our showroom for the following items related to plastic injection molding:

Mono and Multi Couplings

for temperature control, hydraulic, and pneumatic applications

for temperature control, hydraulic, and pneumatic applications

Temperature Control Distributors

including ball valves and mounting kits

including ball valves and mounting kits

Flow Meter

with European, French, or international profile

with European, French, or international profile

Tool Cart NoWWORKBENCH

including tools

including tools

Products for Tool, Mold, and Mechanical Engineering

We manufacture custom parts such as mold inserts and cores according to customer requirements. During your on-site appointment, we will be happy to explain our manufacturing capabilities.

Custom Parts

made of steel, stainless steel, aluminum, and bronze – turned, milled, ground, honed, contoured, and assembled

made of steel, stainless steel, aluminum, and bronze – turned, milled, ground, honed, contoured, and assembled

Mold Bases

including guiding elements, ejectors, and other tooling components

including guiding elements, ejectors, and other tooling components

Coupling Technology

for temperature control, hydraulic, and pneumatic applications

for temperature control, hydraulic, and pneumatic applications

Screws, Standard Parts, and Norm Parts

at attractive prices

at attractive prices

Showroom appointment request

Get an impression for yourself

The showroom is located at the company headquarters at Wilhelmstraße 34, 73650 Winterbach. Book your personal appointment now.